The YT-1000 series of electric-pneumatic valve positioners are devices that receive 4~20mA DC current signals from the control system to accurately adjust the valve opening.

YT-1000 Positioner feature

- High seismic performance, and stable operation in the field with large vibration.

- After more than I million action tests and seismic tests, the stability of the product is ensured.

- Fast reaction speed and high accuracy.

- With simple adjustment, 1/2 range travel control can be achieved.

- Low air consumption, good energy saving.

- The forward/reverse reaction can be easily converted.

- Zero point and span adjustment are very simple.

- Feedback connection is very simple.

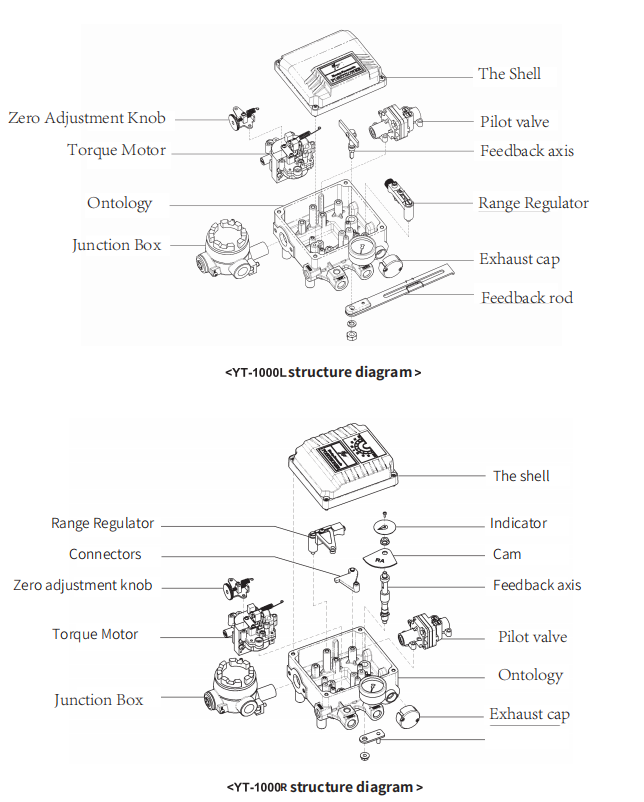

YT-1000 Positioner structure diagram

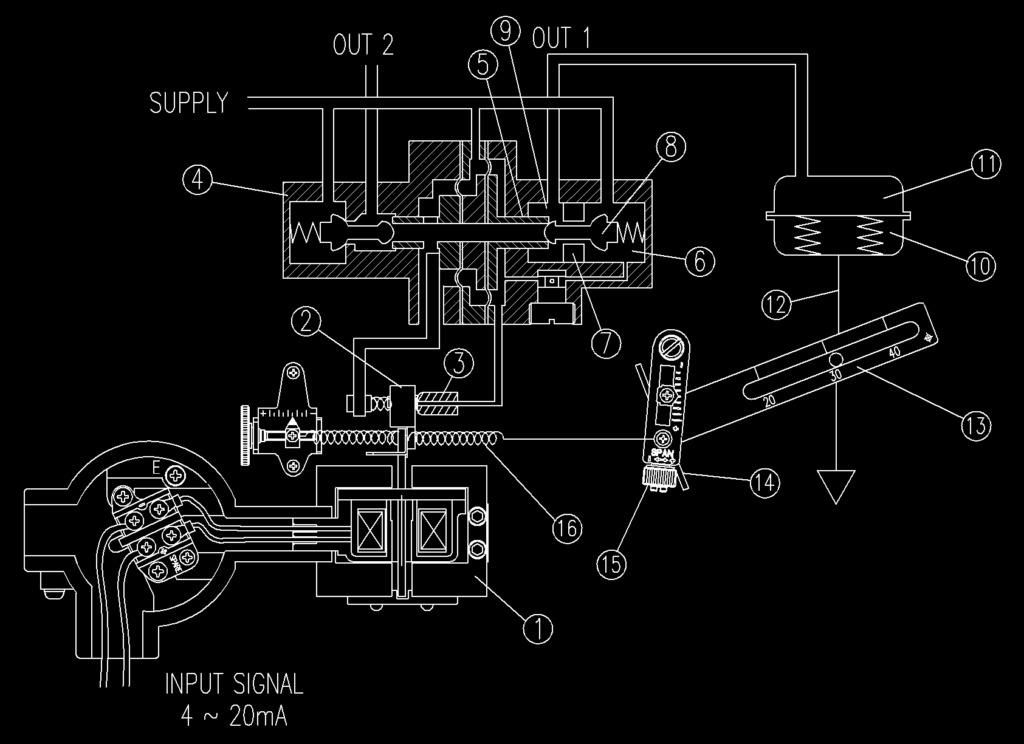

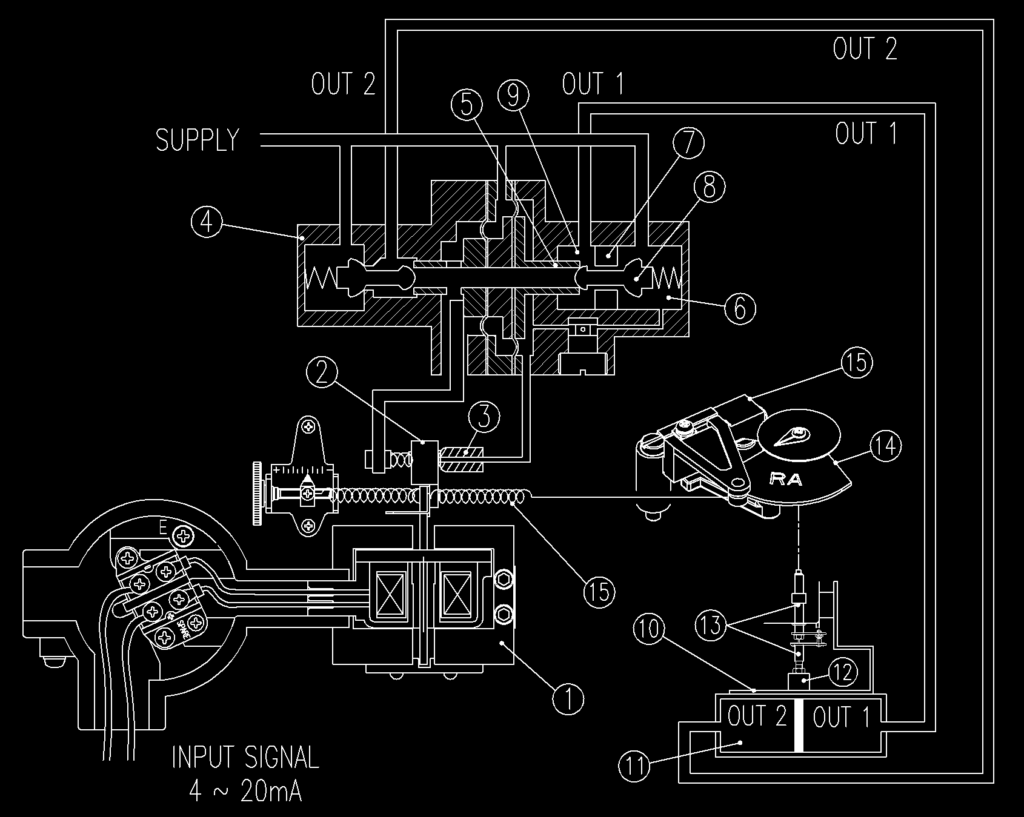

YT-1000 Positioner action principle

In order to open the valve to increase the current signal, the torque motor (①) generates an electromagnetic field, and the baffle (②) receives an electromagnetic field force away from the nozzle (③). The distance between the nozzle (③) and the baffle (③) becomes larger, and the air pressure above the spool (⑤) inside the pilot valve (④) is discharged. The affected spool (⑤) moves to the right and pushes the spool (⑧) blocking the base (⑦) to input air pressure to the actuator (⑩) through the base (⑦). As the interna pressure of the actuator air chamber (⑪) increases, the actuator push rod (②) decreases, and the displacement change of the actuator push rod (②) is transmitted to the skateboard (⑩) by the feedback rod (③). This displacement change is communicated to the range (⑮) feedback rod, which pulls the range spring (⑯). When the force of the range spring (⑰) and the torque motor (①) is in balance, the baffle (②) returns to the original position, and the distance between the baffle (②) and the nozzle (③) is reduced. As the amount of air discharged through the nozzle (③) decreases, the air pressure above the spool (⑤) increases. The spool (⑤) is returned to its original position, and the spool (⑧) reblocks the base (⑦). Stop the air pressure input to the actuator (⑩). When the motion of the actuator (⑩) stops, the locator remains in a stable state.

Product Maintenance and Inspection

The positioner does not operate when the current signal is input.

- Confirm whether the pressure reducing valve supplies air normally. The input pressure must at least exceed 1.4 kgf/cm² above. When sing spring return actuators, the input pressure should be greater than the spring coefficient.

- Confirm whether the current signal and limit are normal. The current signal range is 4-20mA DC.

- Confirm whether the zero position and range adjustment of the positioner are biased to a certain direction, especially whether the zero point setting is too high or too low.

- Confirm whether the nozzle of the positioner is blocked. Confirm that the pressure reducing valve is supplying air normally, manually adjust the baffle, and confirm whether there is air output from the nozzle. If the nozzle is blocked, please send the product to our agent for repair.

- Verify that the feedback lever is correctly connected to the actuator. Please refer to the installation section of this manual for confirmation.

When the outlet 1 pressure rises to the set pressure of the pressure reducing valve and does not decrease.

- Confirm whether the automatic/manual switch leaks air. If air leaks, replace the switch or replace the pilot valve.

- Confirm whether the nozzle and baffle are normal and damaged. If damaged, please contact our company or our agent.

- Confirm whether the constant orifice on the automatic/manual switch is blocked. If blocked, please contact our company or our agent.

When there is pressure output only through the automatic/manual switch.

- Confirm whether the nozzle is blocked. Confirm whether the pressure reducing valve supplies air normally, manually adjust the baffle, and confirm whether the nozzle has air output. If the nozzle is blocked, please send the product to our agent for repair.

When the actuator oscillates.

- Confirm whether the load springs on both sides of the pilot have fallen off. If it comes off, reinstall it correctly.

- Confirm whether the actuator volume is too small. This situation can be solved by loading an orifice to reduce the flow input to the actuator.

- Confirm whether the friction force between the valve rod and the actuator push rod is too large. This situation should be solved by increasing the actuator scale or reducing the friction force of the valve rod.

- If the above three measures cannot solve the oscillation problem, please contact our company or agent.

The actuator only has on/off action, without intermediate adjustment.

- Confirm the action mode of the actuator and positioner. YT-1000 series positioners increase the pressure at outlet 1 as the input signal increases. According to this principle, it is necessary to correctly connect the air circuit. According to this principle, the positive acting actuator range adjustment device. It is necessary to install the actuator range adjustment element in the positive action position and the reaction actuator range adjustment element in the reaction position.

- The double acting actuator is also based on this principle.

When the linearity is poor.

- Confirm whether the installation position of the positioner is correct. In particular, make sure that the feedback lever remains horizontal when inputting a 50% signal. If not horizontal, reinstall the positioner.

- Confirm whether the zero point and range settings are correct, whether the zero point is too low, and whether the range is too high. Especially if the zero point setting is incorrect, the range will also be incorrect, so it is necessary to adjust the zero point first.

- Confirm whether the output pressure of the air filtration pressure reducing valve is constant.

- If the output pressure of the pressure reducing valve fluctuates, replace the pressure reducing valve.