How to Choose the Right Valve for Your Industry

When it comes to fluid control systems, choosing the right valve can greatly impact your system’s efficiency, safety, and longevity.

Two common types used in industrial applications are ball valves and globe valves. But what are their differences, and how do you choose the right one?

In this article, we’ll explore the key differences between ball valves and globe valves in terms of design, function, applications, and pros & cons.

1. Basic Design & Structure

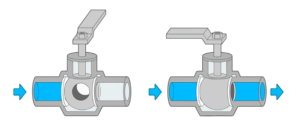

Ball Valve

A ball valve uses a rotating ball with a hole (called a port) through its center.

When the port aligns with the pipeline, flow occurs.

A quarter-turn of the handle closes or opens the valve.

Structure: Simple and compact

Operation: Quarter-turn

Sealing: Tight shut-off

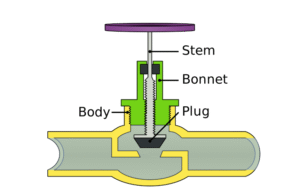

Globe Valve

A globe valve uses a plug or disc that moves up and down perpendicular to the flow path.

Flow control is achieved by throttling the flow via gradual movement.

Structure: Complex with internal baffle

Operation: Multi-turn (usually with a handwheel)

Sealing: Moderate shut-off

2. Function and Flow Control

| Feature | Ball Valve | Globe Valve |

|---|---|---|

| Flow Control | Not ideal for throttling | Excellent for precise throttling |

| Flow Direction | Bidirectional | Usually unidirectional |

| Shut-off Speed | Fast (quarter-turn) | Slower (multi-turn) |

3. Typical Applications

Ball Valves are ideal for:

On/off applications

Systems that require minimal pressure drop

Industrial piping, chemical, water, and oil/gas systems

Globe Valves are preferred in:

Applications needing accurate flow regulation

High-pressure or high-temperature pipelines

Steam systems, cooling water systems, fuel oil systems

4. Pros and Cons

Ball Valve Pros

Quick shut-off (90° turn)Minimal pressure drop

Compact and lightweight

Long service life

Ball Valve Cons

Poor throttling control

Not suitable for slurries or media with particulates

Globe Valve Pros

Excellent throttling performance

Better suited for frequent operation

Suitable for high-pressure applications

Globe Valve Cons

Higher pressure drop

Larger size and heavier weight

Slower operation

5. Which One Should You Choose?

For simple on/off control with minimal maintenance needs — choose a ball valve.

For regulating flow in systems requiring precision and control — go with a globe valve.

The choice depends on your application, fluid type, pressure/temperature requirements, and control needs.

Need Help Choosing the Right Valve?

At DKV Valve, we specialize in manufacturing both ball valves and globe valves with high-quality materials, competitive pricing, and fast lead times.

Our technical team can help you find the best solution for your pipeline system.