Description

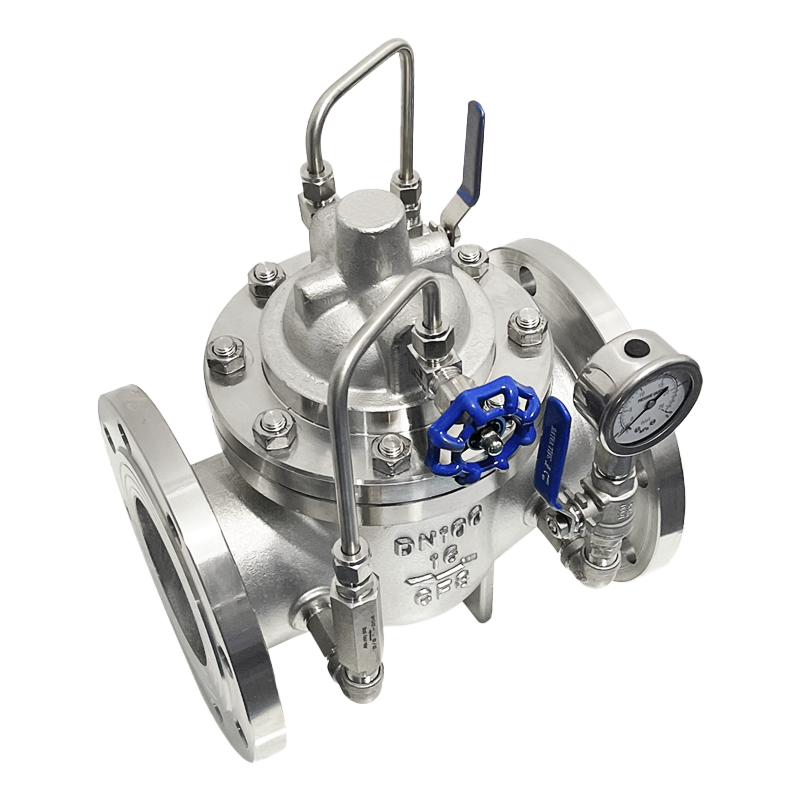

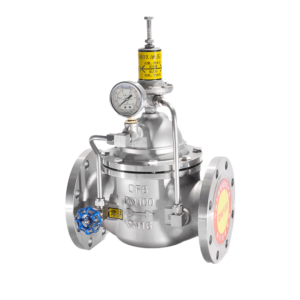

DKV 300X Slow Closing Check Valve

The DKV 300X Slow Closing Check Valve is an intelligent control valve installed at the outlet of water pumps in high-rise buildings and other water supply systems. It is designed to prevent backflow, water hammer, and pressure surges, ensuring safe and stable operation.

This valve integrates three key functions—electric valve, check valve, and water hammer eliminator—providing a comprehensive solution to enhance the safety and reliability of the water supply system.

By combining the technical principles of slow opening, quick closing, and slow closing, the valve effectively eliminates both pump-start and pump-stop water hammer. The valve automatically opens and closes in synchronization with the pump’s start and stop operation—no manual adjustment required.

Featuring a large flow capacity and low pressure loss, the DKV 300X valve is ideal for systems with pipe diameters up to DN600.

Key Features:

-

Combines three functions: electric valve, check valve & water hammer eliminator

-

Automatically opens and closes with pump operation

-

Eliminates water hammer during pump start and stop

-

Ensures smooth flow with minimal pressure loss

-

Suitable for pipelines ≤ DN600

-

Widely used in high-rise building and industrial water supply systems

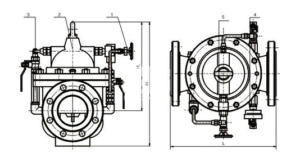

Outline and Connecting Measurememt

1. Needle Valve 2. Main Valve 3. Ball Valve 4.Pressure Gauge 5. Non-return Valve

| Nominal pressure (MPa) |

25 | 32 | 40 | 50 | 60 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| L | 160 | 180 | 203 | 203 | 216 | 241 | 292 | 300 | 356 | 457 | 495 | 540 | 686 | 762 | 864 | 914 | |

| PN 10 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 385 | 390 | 440 | 500 | 585 | 615 | 670 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | |

| PN16 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 480 | 520 | 580 | 640 | 705 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | |

| PN 25 | D | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | |

| H | 172 | 172 | 265 | 265 | 310 | 350 | 460 | 520 | 570 | 695 | 780 | 595 | 1025 | 1080 | 1080 | 1135 | |

| H1 | 106 | 106 | 210 | 210 | 215 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 735 | 610 | 665 | |

Performance Specifications

| Nominal Pressure (MPa) | Test Pressure (MPa) | Applicable Medium | Suitable Medium Temperature |

| 1 | 1.5 | Shell | Clean Water and Sewage without Impurities |

| 1.6 | 2.4 | Seal | ≤80°C |

| 2.5 | 4 | Clean Water and Sewage without Impurities | ≤80°C |

| Part Name | Material |

| Valve Body | Stainless Steel, Cast Iron, Cast Steel, Steel, Ductile Iron |

| Filter | Copper |

| Regulator | Copper |

| Valve Stem | Stainless Steel |

| Diaphragm and Pressure Plate | Nitrile Rubber, Ductile Iron |

| Upper Cover | Ductile Iron, Bronze |

| Slow – closing Valve Plate | Stainless Steel |

| Spring | Silicon – Manganese Steel, Stainless Steel |

| Large Valve Disk | Ductile Iron |

| Valve Seat | Copper, Stainless Steel |

| Diaphragm Seat | Cast Iron, Cast Steel, Steel, Ductile Iron |

| Regulating Valve | Copper |

| Filter | Copper |