Description

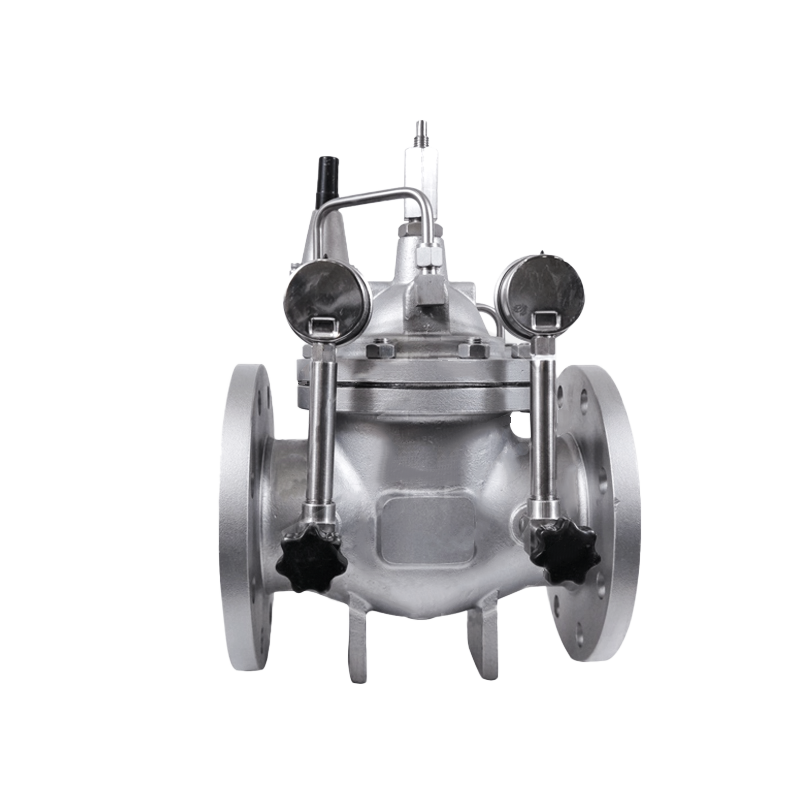

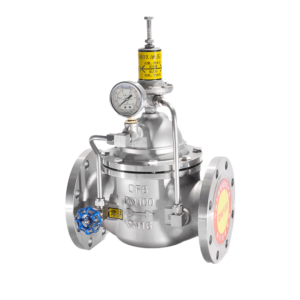

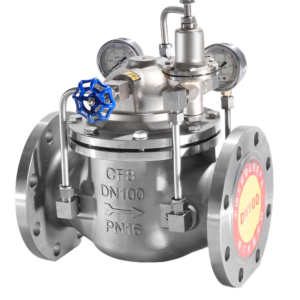

DKV 400X Flow Control Valve

The DKV 400X Flow Control Valve is a multifunctional valve that precisely regulates flow using a high-accuracy pilot control system. It is ideal for distribution pipelines where both flow and pressure must be maintained within specific limits—keeping the preset flow constant and preventing excessive flow beyond the designated value.

By appropriately reducing upstream high pressure, the valve ensures stable downstream flow even when inlet pressure fluctuates. Unlike traditional throttling valves that rely on orifice plates or mechanical flow restrictions, the 400X valve uses a pilot-operated mechanism to minimize energy loss during throttling and improve overall efficiency.

In emergency situations, the 400XA model can completely shut off flow to prevent system damage or product loss. With high control sensitivity, reliable operation, easy adjustment, and long service life, the DKV 400X is a dependable solution for modern water supply and industrial systems.

Key Features:

-

Precise pilot-operated flow control with stable performance

-

Maintains constant flow regardless of inlet pressure variations

-

Minimizes energy loss through optimized throttling design

-

Emergency shutoff function (400XA type) for added safety

-

High sensitivity, easy calibration, long service life

-

Ideal for water supply, distribution, and industrial pipeline systems

| Part Name | Material |

| Valve Body | Stainless Steel, Cast Iron, Cast Steel, Steel, Ductile Iron |

| Filter | Copper |

| Regulator | Copper |

| Valve Stem | Stainless Steel |

| Diaphragm and Pressure Plate | Nitrile Rubber, Ductile Iron |

| Upper Cover | Ductile Iron, Bronze |

| Slow – closing Valve Plate | Stainless Steel |

| Spring | Silicon – manganese Steel, Stainless Steel |

| Large Valve Disk | Ductile Iron |

| Valve Seat | Copper, Stainless Steel |

| Diaphragm Seat | Cast Iron, Cast Steel, Steel, Ductile Iron |

| Regulating Valve | Copper |

| Filter | Copper |

Performance Specifications

| Nominal Pressure (MPa) | Test Pressure (MPa) | Applicable Medium | Suitable Medium Temperature |

| 1 | 1.5 | Shell | Clean Water and Sewage without Impurities |

| 1.6 | 2.4 | Seal | ≤80°C |

| 2.5 | 4 | Clean Water and Sewage without Impurities | ≤80°C |

Outline and Connecting Measurememt

| Nominal pressure (MPa) |

25 | 32 | 40 | 50 | 60 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| L | 160 | 180 | 203 | 203 | 216 | 241 | 292 | 300 | 356 | 457 | 495 | 540 | 686 | 762 | 864 | 914 | 1067 | |

| PN 10 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 385 | 390 | 440 | 500 | 585 | 615 | 670 | 780 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | |

| PN16 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 480 | 520 | 580 | 640 | 705 | 840 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | |

| PN 25 | D | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | |

| H | 172 | 172 | 265 | 265 | 310 | 350 | 460 | 520 | 570 | 695 | 780 | 595 | 1025 | 1080 | 1080 | 1135 | 1270 | |

| H1 | 106 | 106 | 210 | 210 | 215 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 735 | 610 | 665 | 725 | |