Description

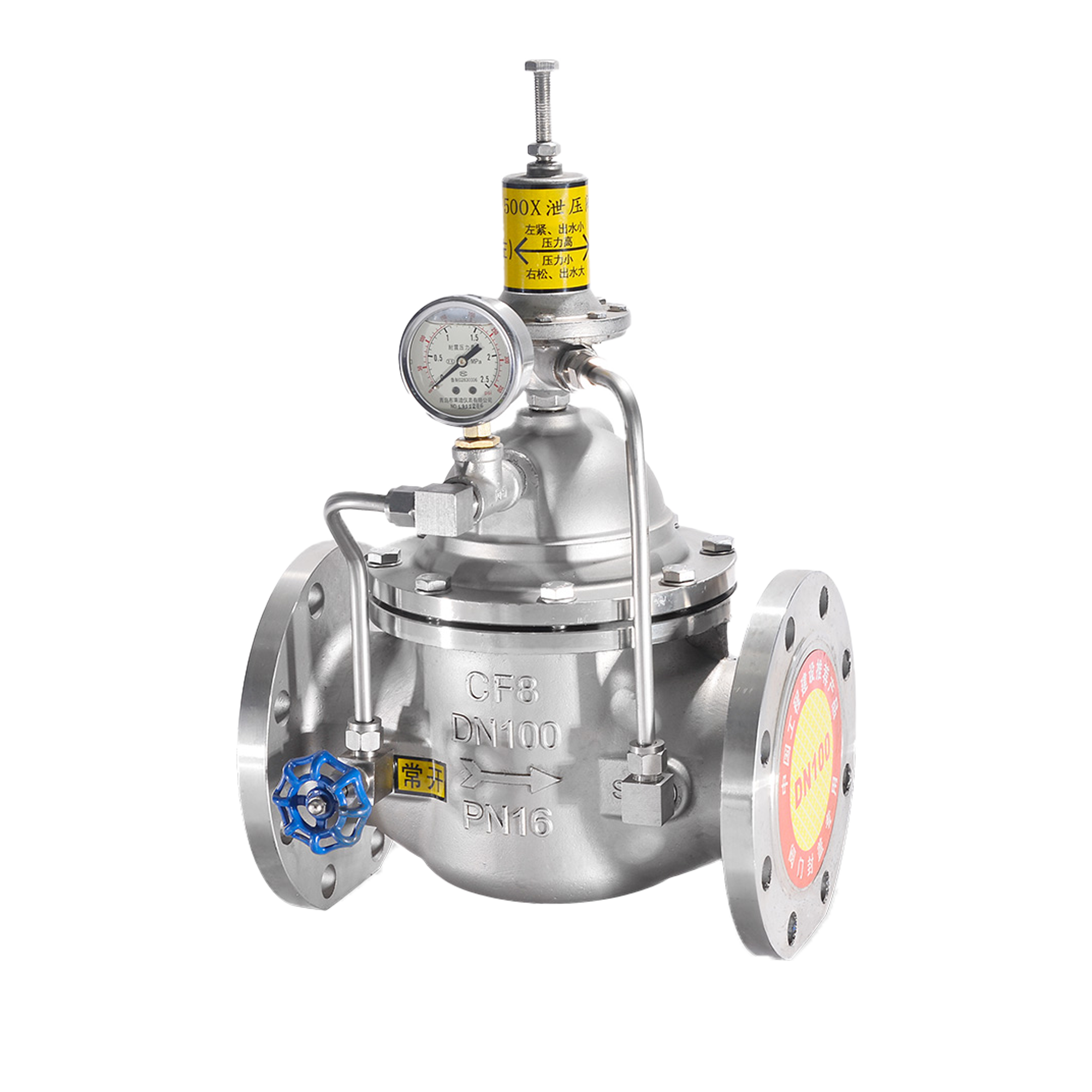

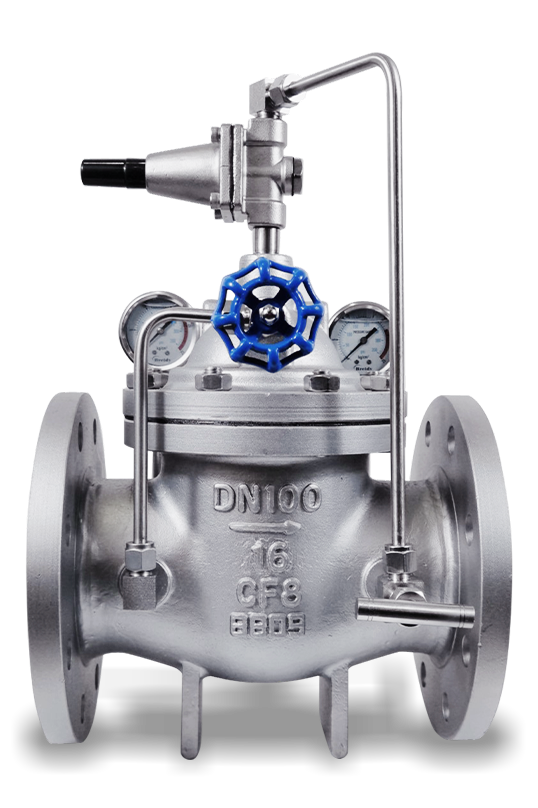

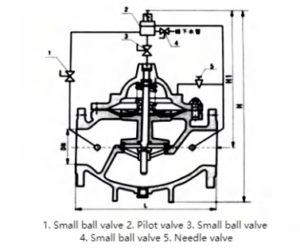

DKV 500X Pressure Relief Valve

The DKV 500X Pressure Relief Valve is designed primarily for fire protection and water supply systems to prevent overpressure and maintain stable system pressure. It also effectively reduces water hammer impact when the fire pump is turned off, serving as a water hammer eliminator for large water supply networks.

A self-cleaning filter is integrated into the valve’s control system inlet. By utilizing fluid dynamics, it prevents suspended particles with larger size or higher density from entering the control system, ensuring smooth and reliable operation.

With stable performance, high structural strength, and long service life, the DKV 500X valve ensures safe and efficient operation in various applications. It is suitable for pipelines with diameters up to DN600.

Key Features:

-

Prevents overpressure in fire and water supply systems

-

Reduces water hammer impact and protects equipment

-

Built-in self-cleaning filter ensures smooth flow and reliability

-

Stable operation with high strength and long service life

-

Suitable for pipelines ≤ DN600

-

Applications: Fire protection, municipal, and industrial water systems

| Part Name | Material |

| Valve Body | Stainless Steel, Cast Iron, Cast Steel, Steel, Ductile Iron |

| Filter | Copper |

| Regulator | Copper |

| Valve Stem | Stainless Steel |

| Diaphragm and Pressure Plate | Nitrile Rubber, Ductile Iron |

| Upper Cover | Ductile Iron, Bronze |

| Slow – closing Valve Plate | Stainless Steel |

| Spring | Silicon – manganese Steel, Stainless Steel |

| Large Valve Disk | Ductile Iron |

| Valve Seat | Copper, Stainless Steel |

| Diaphragm Seat | Cast Iron, Cast Steel, Steel, Ductile Iron |

| Regulating Valve | Copper |

| Filter | Copper |

Outline and Connecting Measurememt

| Nominal pressure (MPa) |

25 | 32 | 40 | 50 | 60 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| L | 160 | 180 | 203 | 203 | 216 | 241 | 292 | 300 | 356 | 457 | 495 | 540 | 686 | 762 | 864 | 914 | 1067 | |

| PN 10 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 385 | 390 | 440 | 500 | 585 | 615 | 670 | 780 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | |

| PN16 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 480 | 520 | 580 | 640 | 705 | 840 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | |

| PN 25 | D | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | |

| H | 172 | 172 | 265 | 265 | 310 | 350 | 460 | 520 | 570 | 695 | 780 | 595 | 1025 | 1080 | 1080 | 1135 | 1270 | |

| H1 | 106 | 106 | 210 | 210 | 215 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 735 | 610 | 665 | 725 | |

Performance Specifications

| Nominal Pressure (MPa) | Test Pressure (MPa) | Applicable Medium | Suitable Medium Temperature |

| 1 | 1.5 | Shell | Clean Water and Sewage without Impurities |

| 1.6 | 2.4 | Seal | ≤80°C |

| 2.5 | 4 | Clean Water and Sewage without Impurities | ≤80°C |