Description

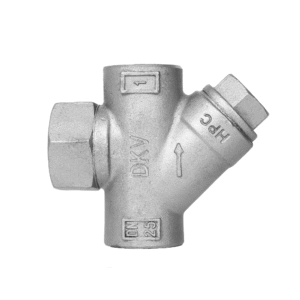

DKV Float Ball Steam Trap efficiently discharges large volumes of condensate without the need for adjustment or replacement of internal components throughout its entire pressure range. Its low subcooling temperature ensures rapid condensate removal, making it ideal for applications with high condensate loads.

The lever float design provides stable and reliable operation, maintaining continuous drainage even under varying pressures. Widely used in industrial steam heating systems, large heat exchangers, dryers, and jacketed vessels, the DKV float ball steam trap delivers energy-efficient performance and long service life in demanding environments.

Outline and Connecting Measurememt

| No. Part | Material |

| 1 Body | Cast iron |

| 2 Cover Studs and Nuts | Steel |

| 3 Cover Gasket | Reinforced Exfoliated Graphite |

| 4 Cover | Cast Iron |

| 5 Main Valve Assembly | Stainless Steel |

| 6 Main Valve Assembly | Gasket Reinforced Exfoliated Graphite |

| 7 Main Valve Assembly Studs and Nuts | Stainless Steel |

| 8 Ball Float and Lever | Stainless Steel |

| 9 Air Vent Assembly | Stainless Steel |

| 10 Air Vent Seat Gasket | Stainless Steel |

| DN | L | H | h | W |

| 15 | 150 | 250 | 190 | 118 |

| 20 | 150 | 250 | 190 | 118 |

| 25 | 160 | 250 | 190 | 118 |

| 32 | 230 | 335 | 270 | 175 |

| 40 | 230 | 335 | 270 | 175 |

| 50 | 230 | 350 | 280 | 175 |