Description

H71W Wafer Check Valve

The H71W Wafer Check Valve is designed to allow liquid or air to flow in only one direction, effectively preventing backflow in piping systems. Its compact wafer design makes it easy to install between flanges, saving space while maintaining reliable operation.

Constructed from durable materials, the H71W ensures smooth, trouble-free performance and long-term reliability. Selecting the correct type, size, and specification guarantees efficient operation with minimal energy consumption.

Key Features:

-

Type: Wafer Check Valve

-

Function: Prevents backflow, ensures one-way flow

-

Design: Compact wafer style for space-saving installation

-

Durable construction for reliable, long-term use

-

Applications: Water supply, HVAC, chemical, and industrial systems

| Main part metarial | Body | WCB(A105 | 2G1Cr18Ni9Ti | CF8(304) | CF8(304L) | 2G1Cr18Ni12Mo2Ti | 0Cr17Ni12Mo2 | 0Cr17Ni14Mo2 |

| Body | CF8 | CF8 | CF8 | CF3 | CF8M | CF8M | CF3M | |

| Valve Shaft | Cr13 | Cr18Ni9T | Cr18Ni9 | Cr19Ni10 | 1Cr18Ni12Mo2T | Cr17Ni12Mo2 | Cr17Ni14Mo2 | |

| Springs | Cr18Ni9 | Cr18Ni9 | Cr18Ni9 | Cr19Ni10 | Cr17Ni12Mo2 | Cr17Ni12Mo2 | Cr17Ni14Mo2 | |

| Applicable conditions | Medium | Water, Gas and Oils | Corrosive Media such as Nitric Acid | Oxidizing Media | Acetic Acid and Other Corrosive Media | Urea and Other Corrosive Media | ||

| Temperature | -29~425℃ | -196~540℃ | -196-425℃ | -196~540℃ | -196~455℃ | |||

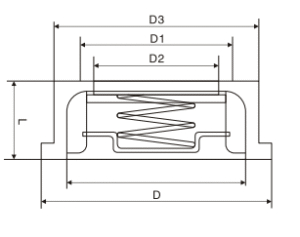

Outline and Connecting Measurememt

| PN MPa |

DN (mm) | Size(mm) | Weight (kg) |

Flange(For Refer) | |||||||

| L | D | D3 | D2 | D1 | Bolt Hole Center Circle Diameter D1 | Bolt Quantity | Bolt Diameter | Bolt Length L1 | |||

| PN1.0 MPa PN1.6 MPa |

15 | 30 | 50 | 15 | 44 | 25 | 0.12 | 65 | 4 | M12 | 75 |

| 20 | 30 | 60 | 19 | 52 | 30 | 0.24 | 75 | 4 | M12 | 90 | |

| 25 | 30 | 68 | 24 | 60 | 36 | 0.34 | 85 | 4 | M12 | 90 | |

| 32 | 35 | 80 | 31 | 72 | 43 | 0.53 | 100 | 4 | M16 | 100 | |

| 40 | 35 | 88 | 39 | 74 | 52 | 0.80 | 110 | 4 | M16 | 105 | |

| 50 | 40 | 102 | 48 | 98 | 62 | 1.2 | 125 | 4 | M16 | 125 | |

| 65 | 50 | 125 | 63 | 117 | 75 | 2.2 | 145 | 4 | M16 | 130 | |

| 80 | 60 | 140 | 78 | 128 | 90 | 3.1 | 160 | 8 | M16 | 135 | |

| 100 | 68 | 165 | 98 | 112 | 5.7 | 180 | 8 | M16 | 150 | ||

| 125 | 80 | 190 | 123 | 132 | 10 | 210 | 8 | M16 | 180 | ||

| 150 | 100 | 213 | 148 | 158 | 14 | 240 | 8 | M20 | 210 | ||

| 200 | 110 | 265 | 198 | 208 | 24 | 295 | 8 | M20 | 240 | ||

| 250 | 132 | 333 | 248 | / | 208 | 35 | 350 | 8 | M20 | 260 | |

| 300 | 150 | 380 | 280 | / | |||||||

Product Details