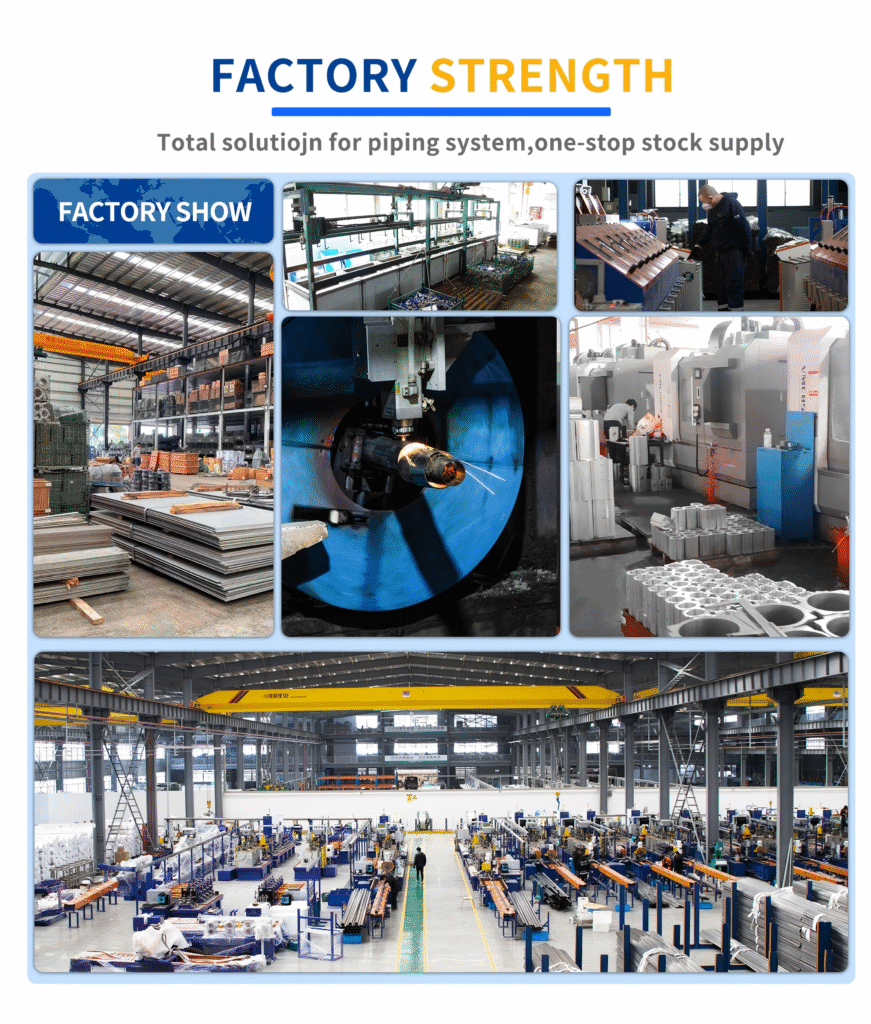

Description

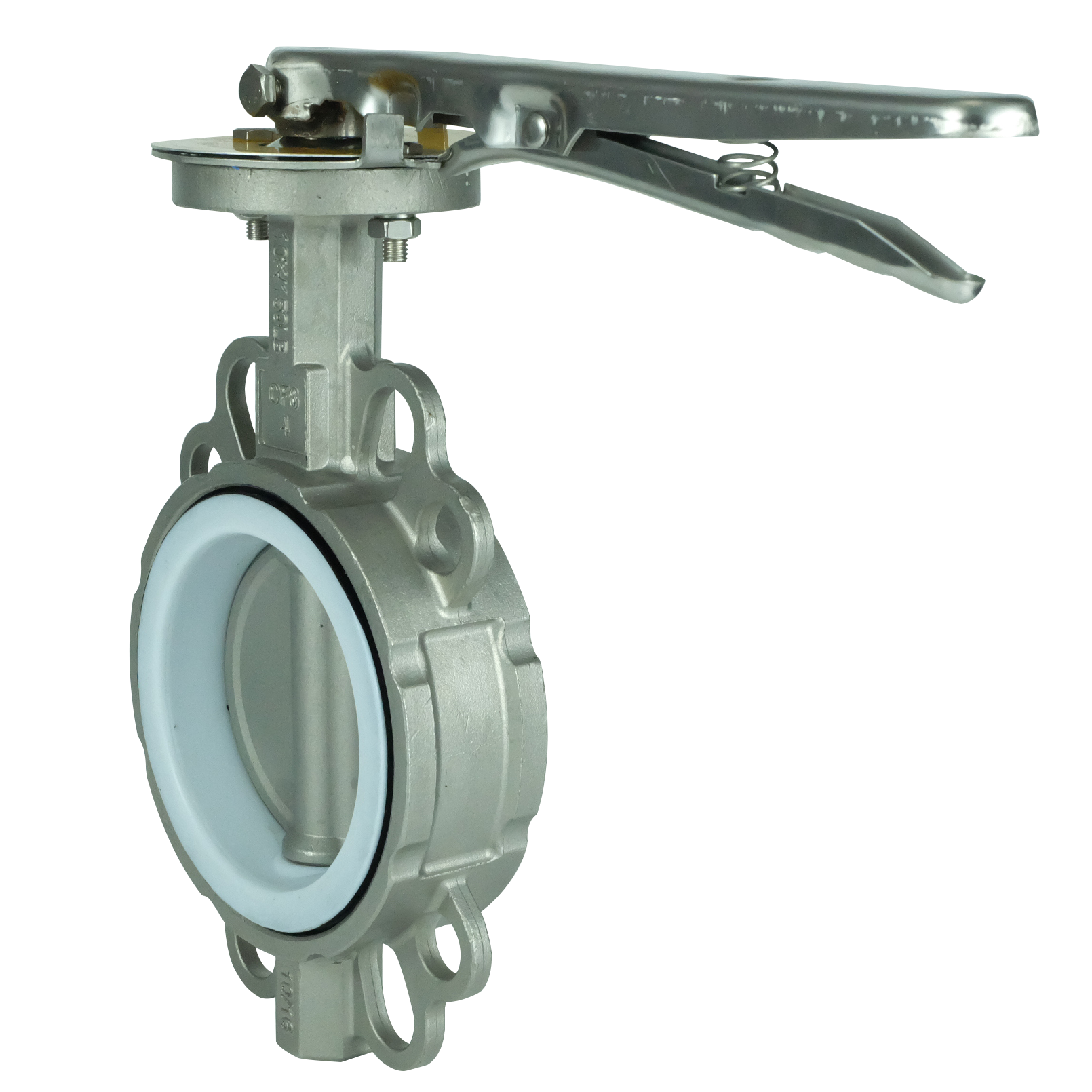

Wafer-Style Butterfly Valve

Widely used in both light and heavy industries as well as building pipelines.

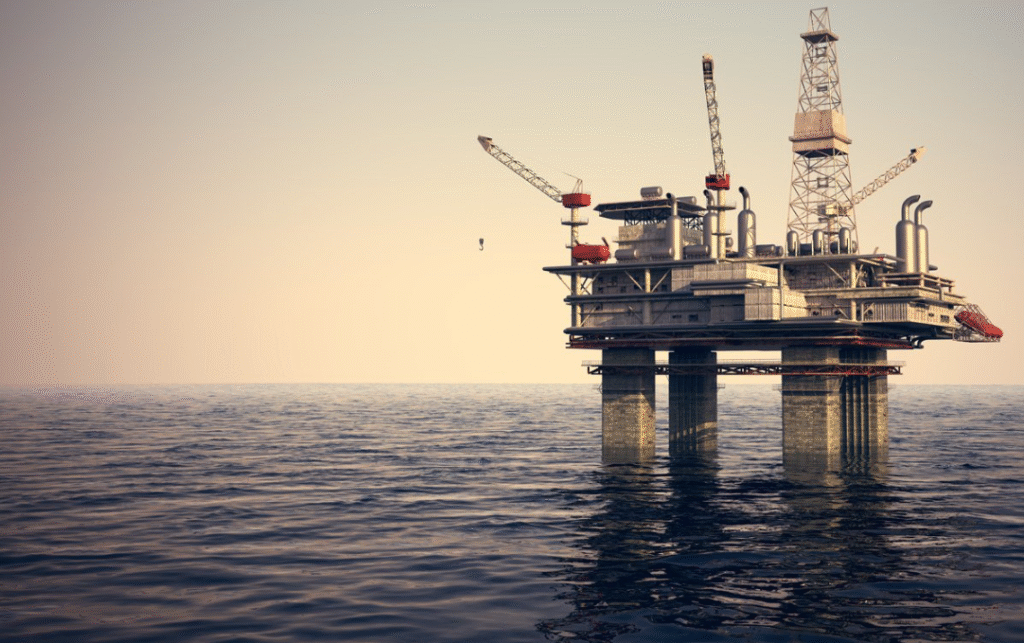

Applications: Chemical, Petrochemical, Oil, Paper, Mining, Power, LPG, Food, Water Supply and Drainage, Municipal Engineering, Machinery, Electronics, and Urban Construction.

Butterfly Valve – Key Features

-

Easy and quick operation with minimal effort; low flow resistance; suitable for frequent use.

-

Simple structure, compact size, and lightweight design.

-

Capable of handling slurry with minimal fluid retention at the pipe end.

-

Reliable sealing performance under low pressure.

-

Good flow regulation capability.

Installation Guidelines

-

Keep the disc in the closed position during installation.

-

Determine the opening position according to the disc’s rotation angle.

-

For valves with a bypass valve, open the bypass first before operation.

-

Follow the installation manual carefully; large valves should be installed on a firm foundation.

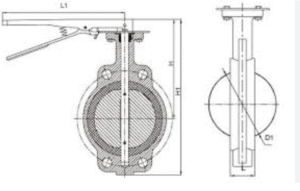

Outline and Connecting Measurememt

DN L Z×Фd D0 50 43 2×Ф19 120 65 46 2×Ф19 140 80 46 2×Ф19 50 100 52 2×Ф19 175 125 56 2×Ф23 210 150 60 2×Ф23 240 200 68 2×Ф25 290 250 78 2×Ф25 355 300 78 2×Ф25 400

|

Item

|

Butterfly Value

|

|

Application

|

General

|

|

Port Size

|

DN50-DN200

|

|

Warranty

|

1 year

|

|

Place of Origin

|

China

|

|

Power

|

Manual

|

|

Temperature of Media

|

Normal Temperature

|

|

Brand Name

|

DKV

|

|

Media

|

Water

|

|

Customized Support

|

OEM, ODM

|

|

Body Material

|

Stainless Steel 304

|

|

Seal Material

|

PTFE

|

|

Disc

|

Stainless Steel 304

|

|

Working pressure

|

PN10/16

|

|

Work Temperature

|

-10°C to 120°C

|

|

Application Field

|

Petrochemical, Oil & Gas, Marine, and Industrial Applications

|

Product Details