A check valve is also known as a non-check valve. It is a self-acting valve. It uses the working fluid in the tube as a piston to move a valve disc in order to shut open the valve. When the flow of product ceases, the check valve disc will close. It can effectively prevent the medium in the pipeline from flowing back. This is helpful for the pipeline in terms of effectiveness and safety.

The check valve is installed to ensure the flow direction of the water inside the water pump. Thereby ensuring the normal operation of the water pump.

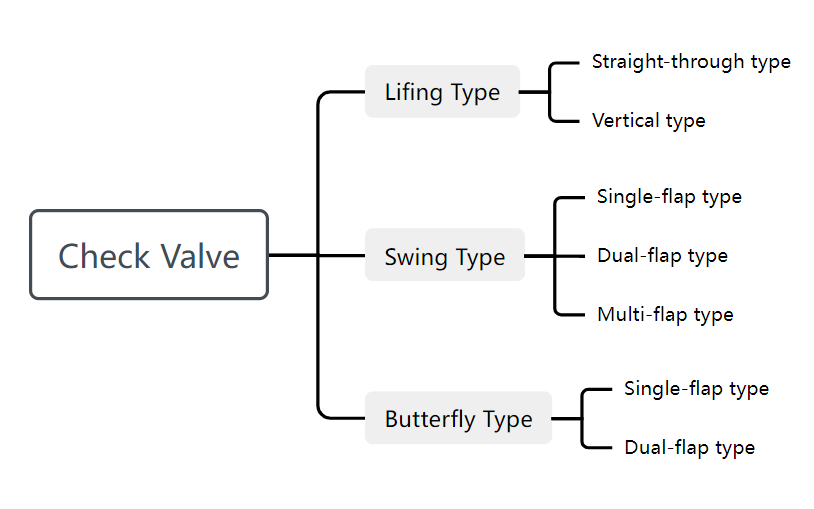

Check valves can be classified structurally into three: lift check valves, swing check valves and butterfly check valves. The types of lift check valves can be defined as two, namely vertical and straight-through type. The types of swing check valves can be considered as three, that is, single-flap, double-flap and multi-flap. Butterfly check valves can be divided into butterfly double-flap and butterfly single-flap. The above check valves can be divided into four types in terms of connection: threaded connection, flange connection, welding and wafer connection.

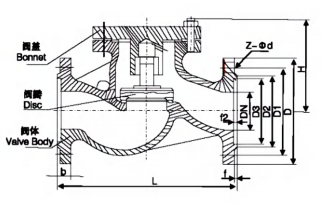

The disc of the lift check valve will be moving up or downward on the central vertical axis of the valve body. Medium flow downstream so the medium thrust opening the disc valve. And when the medium flow is cut off, the disc valve is self-sagged and rests on the valve seat from where it will perform the function of checking the back flow of the medium.

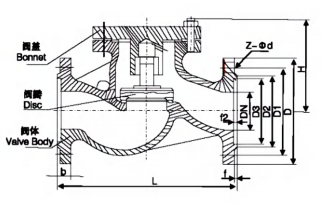

Straight-through lift check valve:

The direction of the medium inlet and outlet channels is perpendicular to the direction of the valve seat channel. The lift horizontal flap check valve can only be installed on horizontal pipes and can generally be used on horizontal pipes with a nominal diameter of 50mm.

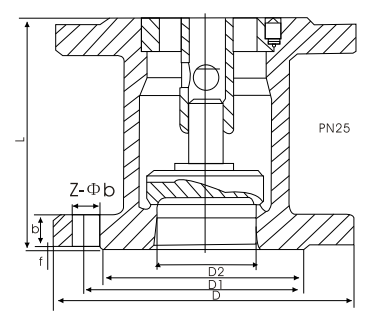

Vertical lift check valve

The direction of the medium inlet and outlet channels is the same as the direction of the valve seat channel. The lift vertical flap check valve can only be installed on vertical pipes, and its flow resistance is smaller than that of the straight-through type. The lift type has better sealing than the swing type and greater fluid resistance.

Which check valve has better sealing performance?

Straight-through lift check valve>vertical lift check valve>swing check valve

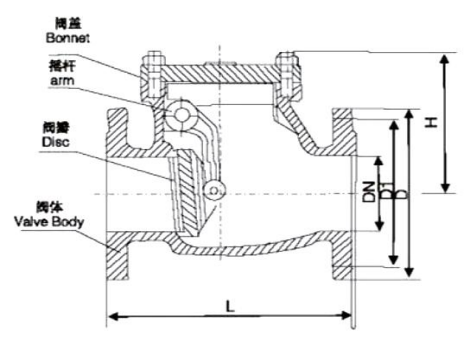

The disc of the swing check valve is disc-shaped and rotates around the rotating shaft of the valve seat channel. Because the channel inside the valve is streamlined, the flow resistance is smaller than that of the lift check valve. It is suitable for large-caliber occasions with low flow rate and infrequent flow changes, but not suitable for pulsating flow. Its sealing performance is not as good as that of the lift check valve. Swing check valves are divided into single-flap type, double-flap type and multi-flap type. These three types are mainly divided according to the valve diameter. The purpose is to prevent the medium from stopping flowing or backflowing and weakening the hydraulic impact.

Types of Swing Check Valves

The installation position of the swing check valve is not restricted. It can be installed on horizontal, vertical or inclined pipelines. If installed on the vertical pipeline, the medium should flow from bottom to top. The swing check valve is not suitable for small-diameter valves. It can be made into valves have a very high working pressure. The nominal pressure can reach 42MPa. The nominal diameter can also be very large, up to 2000mm. Depending on the material of the shell and seal, it can be used for any working medium and any working temperature range. The medium is water, steam, gas, corrosive medium, oil, medicine, etc. The medium working temperature range is between -196-800℃.

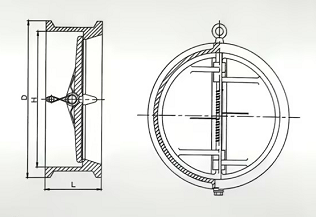

A check valve whose disc rotates around the pin in the valve seat. The butterfly check valve has a simple structure and poor sealing performance. The installation position of the butterfly check valve is not restricted and can be installed on horizontal pipelines, vertical pipelines or inclined pipelines.

Butterfly Check Valve Working Principle

When the medium flows forward, the valve disc is pushed open. When the medium flows reversely, the valve disc closes quickly under the action of the spring and the medium pressure to prevent the medium from flowing back.

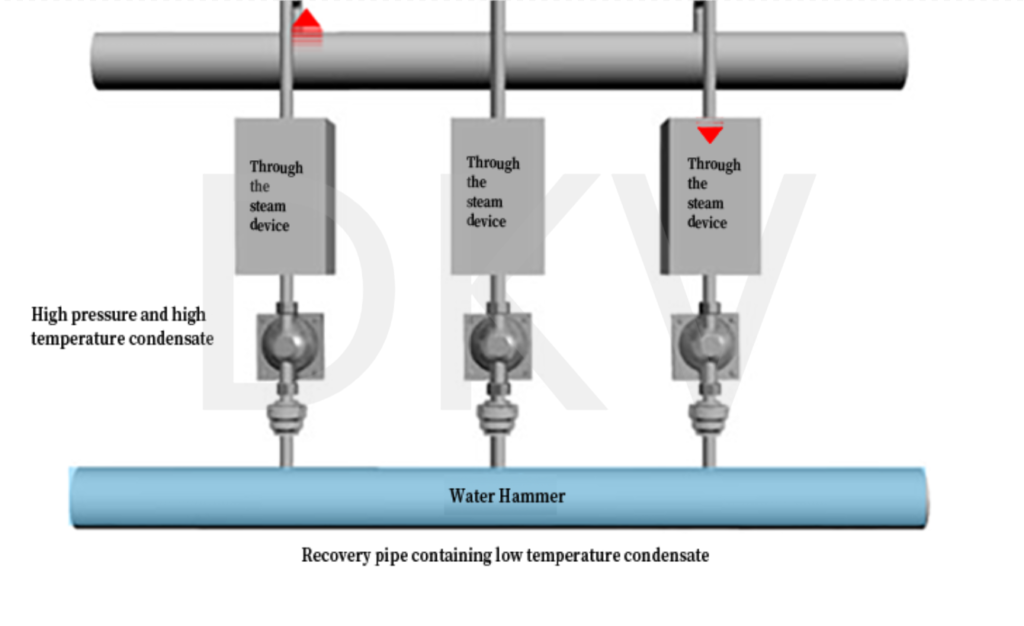

If there is a possibility of condensate backflow, then it is necessary to install a check valve. For example, when the condensate is discharged into a common header pipe, there is a possibility that condensate discharged from other traps will backflow back into the equipment, so a check valve must be installed in this case. It is very important to prevent this kind of backflow because it will not only affect the heating efficiency, but also has a high possibility of damaging the steam trap. On the other hand, if the steam trap outlet is connected to a separate drain pipe to discharge downward, there will be no backflow, and a check valve is not required.