Description

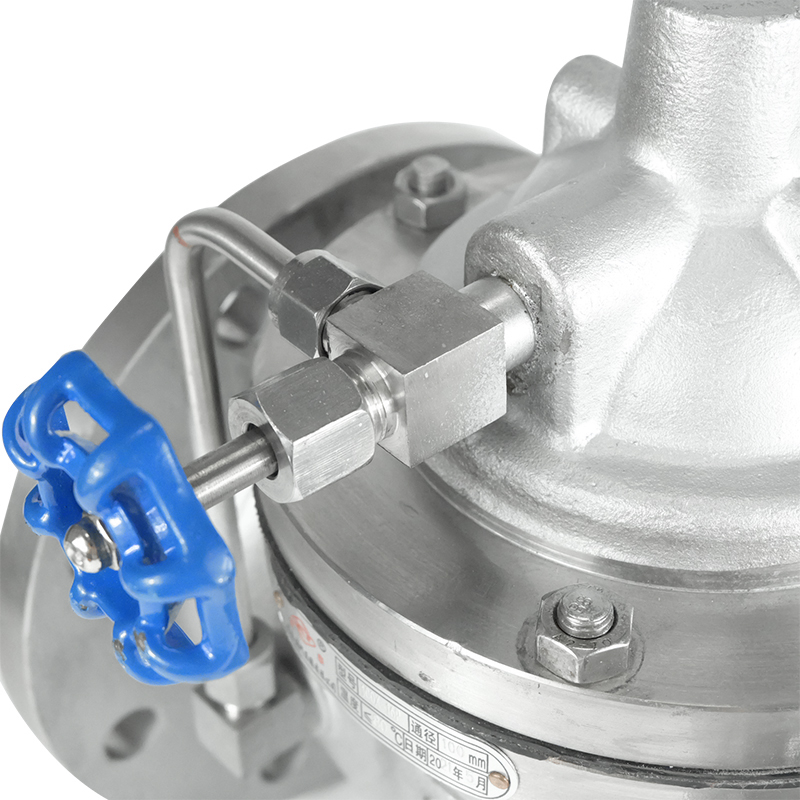

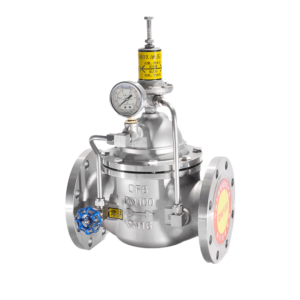

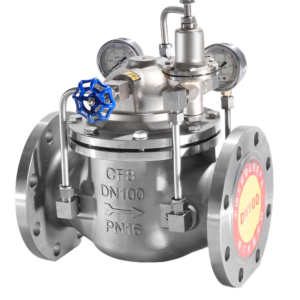

100X Diaphragm Remote Control Float Valve

The 100X diaphragm remote control float valve is a hydraulically operated valve with multiple functions, commonly installed at the water inlets of pools or elevated water towers. It automatically regulates the water level:

-

When the water reaches the set height, the float pilot valve closes the main valve to stop supply.

-

When the water level drops, the float switch opens the main valve to refill the pool.

This design provides precise liquid level control unaffected by water pressure. The valve can be installed at any position according to pool height and space requirements.

Engineered for reliability, the valve features excellent sealing, flexible operation, and long service life. The diaphragm structure ensures high strength and stable performance, making it ideal for pipelines with diameters ≤ DN450 mm, while piston-type valves are recommended for pipelines ≥ DN500 mm.

Key Features:

-

Automatic water level control, not influenced by pressure

-

Easy installation, maintenance, and inspection

-

Reliable sealing and long service life

-

Diaphragm type: suitable for DN ≤ 450 mm

-

Piston type: recommended for DN ≥ 500 mm

-

Applications: Pools, elevated water towers, water supply systems

| Part Name | Material |

| Valve Body | Stainless Steel, Cast Iron, Cast Steel, Steel, Ductile Iron |

| Filter | Copper |

| Regulator | Copper |

| Valve Stem | Stainless Steel |

| Diaphragm and Pressure Plate | Nitrile Rubber, Ductile Iron |

| Upper Cover | Ductile Iron, Bronze |

| Slow – closing Valve Plate | Stainless Steel |

| Spring | Silicon – manganese Steel, Stainless Steel |

| Large Valve Disk | Ductile Iron |

| Valve Seat | Copper, Stainless Steel |

| Diaphragm Seat | Cast Iron, Cast Steel, Steel, Ductile Iron |

| Regulating Valve | Copper |

| Filter | Copper |

Performance Specifications

| Nominal Pressure (MPa) | Test Pressure (MPa) | Applicable Medium | Suitable Medium Temperature |

| 1 | 1.5 | Shell | Clean Water and Sewage without Impurities |

| 1.6 | 2.4 | Seal | ≤80°C |

| 2.5 | 4 | Clean Water and Sewage without Impurities | ≤80°C |

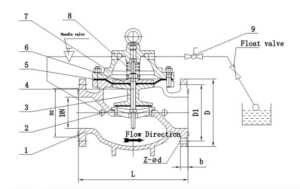

Outline and Connecting Measurememt

Body: Stainless Steel

Seat: Stainless Steel

Disc: 2Cr13+Rubber

Stem: 2Cr13

Diaphragm: Rubber

Gland: Stainless Steel

Bonnet: Stainless Steel

Spring: Steel

Accessories: Stainless Steel

| Nominal pressure (MPa) |

25 | 32 | 40 | 50 | 60 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

| L | 160 | 180 | 203 | 203 | 216 | 241 | 292 | 300 | 356 | 457 | 495 | 540 | 686 | 762 | 864 | 914 | 1067 | 1300 | 1450 | |

| PN 10 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 385 | 390 | 440 | 500 | 585 | 615 | 670 | 780 | 895 | 1010 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | |

| PN16 | D | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 480 | 520 | 580 | 640 | 705 | 840 | 910 | 1020 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 940 | 950 | |

| PN 25 | D | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 | 955 | 1070 |

| D1 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | 875 | 990 | |

| H | 172 | 172 | 265 | 265 | 310 | 350 | 460 | 520 | 570 | 695 | 780 | 595 | 1025 | 1080 | 1080 | 1135 | 1270 | 1460 | 1640 | |

| H1 | 106 | 106 | 210 | 210 | 215 | 215 | 245 | 305 | 365 | 415 | 510 | 560 | 658 | 735 | 610 | 665 | 725 | 865 | 975 | |