Description

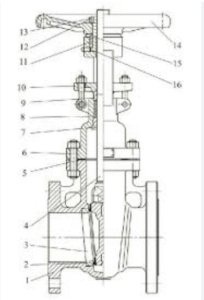

DKV Motorized Flanged Gate Valve

The DKV Motorized Flanged Gate Valve is a high-performance valve designed for precise, automated flow control in industrial pipelines. With flanged connections and a rising or non-rising stem design, it provides leak-proof performance and easy integration into standard piping systems.

Equipped with a reliable electric actuator, the valve allows remote operation and automation, ensuring smooth and accurate flow regulation for water, oil, gas, and non-corrosive media. Constructed from stainless steel, carbon steel, or cast iron, it offers excellent durability, corrosion resistance, and long service life.

Widely used in HVAC, water treatment, chemical, and industrial automation systems, the DKV Motorized Flanged Gate Valve delivers high precision, dependable operation, and minimal maintenance.

Key Features:

-

Electric actuator for automated, precise control

-

Flanged connection for secure, leak-proof installation

-

Rising or non-rising stem design for versatile operation

-

Durable construction with stainless steel, carbon steel, or cast iron options

-

Suitable for water, oil, gas, and compatible media

-

Ideal for industrial automation, chemical, and water treatment systems

Outline and Connecting Measurememt

| Optional Function of Electric Actuator | Switching Type, Regulating Type, Intelligent Body Type |

| Voltage | AC220V AC380 |

| Nominal Diameter | DN40mm~DN1000mm |

| Nominal Pressure | PN1.0Mpa~PN6.4Mpa |

| Applicable Temperature | -30~+550℃ |

| Connection Mode | Flange type |

| Valve Body Material | Cast Steel, Stainless Steel |

| Valve Disc Material | Cast Steel, Stainless Steel |

| Valve Seat Lining | PPL, Body Material |

| Applicable Medium | Water, Oil, Steam, Acid, Alkali, Ammonia, Urea, Sulfur-Containing Natural Gas, etc |

| (DN) | (MPa) | (MPa) | |||||||||||||

| 25 | 0.6 | 0.6 | 160 | 124 | 31 | 115 | 85 | 4-14 | ZA5-14 | 443 | 133 | 0.12 | 18 | ||

| 32 | 165 | 145 | 40 | *140 | 100 | 4-18 | |||||||||

| 40 | 190 | 157 | 50 | *150 | 110 | 4-18 | |||||||||

| 50 | 210 | 160 | 60 | 160 | 125 | 4-18 | ZA10-18 | 552 | 425 | 0.25 | 71 | ||||

| 65 | 250 | 199 | 74 | 180 | 145 | 4-18 | ZA15-15 | 552 | 425 | 305 | 0.37 | 80 | |||

| 80 | 300 | 222 | 88 | 195 | 160 | 4-18 | ZA30-18 | 552 | 425 | 305 | 0.75 | 92.9 | |||

| 100 | 350 | 250 | 106 | 215 | 180 | 8-18 | ZA30-18 | 552 | 425 | 305 | 0.75 | 101 | |||

| 125 | 430 | 318 | 134 | 245 | 210 | 8-18 | 305 | ||||||||

| 150 | 500 | 350 | 158 | 280 | 240 | 8-23 | 1000 | ||||||||

| 200 | 0.4 | 0.4 | 650 | 446 | 206 | 335 | 295 | 8-23 | 1174 | ZA14-18 | 766 | 390 | 305 | 1.1 | 265 |

| 250 | 800 | 516 | 256 | *395 | 350 | 12-23 | |||||||||

| 300 | 950 | 562 | 304 | *445 | 400 | 12-23 |