邮箱:dkv@dkvchina.com

联系方式:+8613690635385

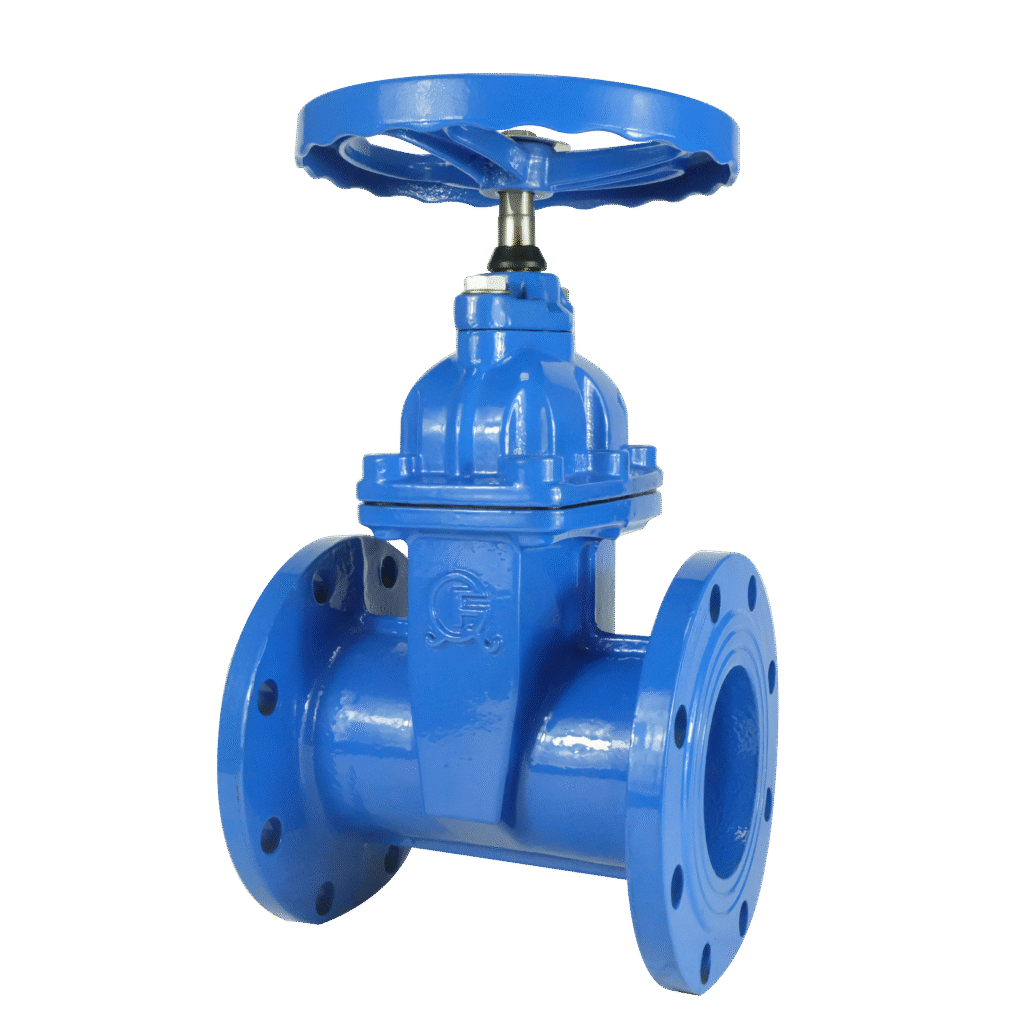

DKV Valve provides high quality gate valve products. Since 1981, the DKV team has been developing and supplying gate valves in China. We offer gate valves in stainless steel, cast iron, cast steel, brass and other materials. Please contact us for more information.

Showing all 11 resultsSorted by price: low to high

A gate valve is a linear motion valve primarily used to start or stop fluid flow in pipelines. It features a wedge-shaped or parallel gate that moves vertically with the stem to open or close the flow path. By rotating the handwheel, the gate lifts completely out of the flow passage or seats tightly against the valve seat, ensuring minimal pressure drop when fully open and reliable shutoff when closed.

At DKV VALVE, we understand the importance of safety valves in maintaining pipeline transportation. Our globe valves have excellent designs and CE, ISO, and TS certifications. When used efficiently, DKV provides quality assurance.

Selecting the right material for gate valves is essential to guarantee reliable performance, durability, and safety across a wide range of applications. The material choice should be based on factors such as operating pressure, temperature conditions, media compatibility, and environmental challenges. Common materials for gate valves include stainless steel, cast iron, and cast steel. Below, we outline their pressure and temperature limits, suitable environments, compatible media, and distinct advantages to help you make informed decisions.

Temperature Range: -254°C to 649°C

Environment: Corrosive or hygienic settings (e.g., chemical plants, food processing, marine industries)

Media: Acids, alkalis, steam, water, oil, and gas

Features: Outstanding corrosion resistance, durability, and mechanical strength. Provides reliable shutoff in demanding environments, making it suitable for extreme temperatures, high-pressure systems, and sanitary applications.

Temperature Range: -29°C to 232°C

Environment: Low-pressure systems (e.g., HVAC, water supply, irrigation)

Media: Water, air, and other non-corrosive fluids

Features: Economical and easy to machine, offering reliable shutoff in low-pressure applications. However, less resistant to corrosion and not ideal for aggressive media. Best suited for budget-friendly, light-duty service.

Temperature Range: -268°C to 593°C

Environment: High-pressure and high-temperature systems (e.g., oil & gas, petrochemical, power plants)

Media: Steam, oil, gas, and corrosive or aggressive fluids

Features: Robust construction with excellent strength and thermal stability. Designed to handle pressure surges and demanding industrial conditions, offering reliable shutoff and long service life.

Temperature Range: -40°C to 120°C

Environment: Residential and light industrial systems (e.g., plumbing, water distribution, HVAC)

Media: Water, air, and non-corrosive fluids

Features: Lightweight and corrosion-resistant with good machinability. Offers reliable shutoff for low to medium-pressure applications and is ideal for household or commercial water systems.

Let’s build the world together.

Selecting the proper connection method for globe valves ensures system integrity, leak prevention, and operational efficiency. Here’s a breakdown of threaded, flanged, and welded connections, including their applications, pressure limits, and key characteristics:

Applications: Small-scale or low-pressure systems (e.g., residential plumbing, irrigation, HVAC).

Pressure: Up to 300 psi.

Features: Compact and easy to install without welding. Cost-effective for light-duty service but not recommended for large diameters or heavy industrial use.

Applications: Industrial pipelines requiring frequent inspection or maintenance (e.g., oil refineries, water treatment plants, chemical industries).

Pressure: Up to 2500 psi.

Features: Strong bolt-and-gasket sealing with excellent leak resistance. Easy to disassemble for maintenance, but requires more installation space and higher cost.

Applications: Permanent, high-pressure and high-temperature systems (e.g., power plants, petrochemical pipelines).

Pressure: Exceeds 2500 psi.

Features: Provides permanent, leak-tight connections with no risk of gasket leakage. Best suited for critical, vibration-prone environments. Requires professional welding (e.g., butt-weld per ASME B16.25) and does not allow easy disassembly.

Poly Center T41601, Le Cong Town, Shunde District, Foshan City, Guangdong Province, China

We will contact you within 1 working day, please pay attention to the email with the suffix “dkvchina.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@dkvchina.com”.