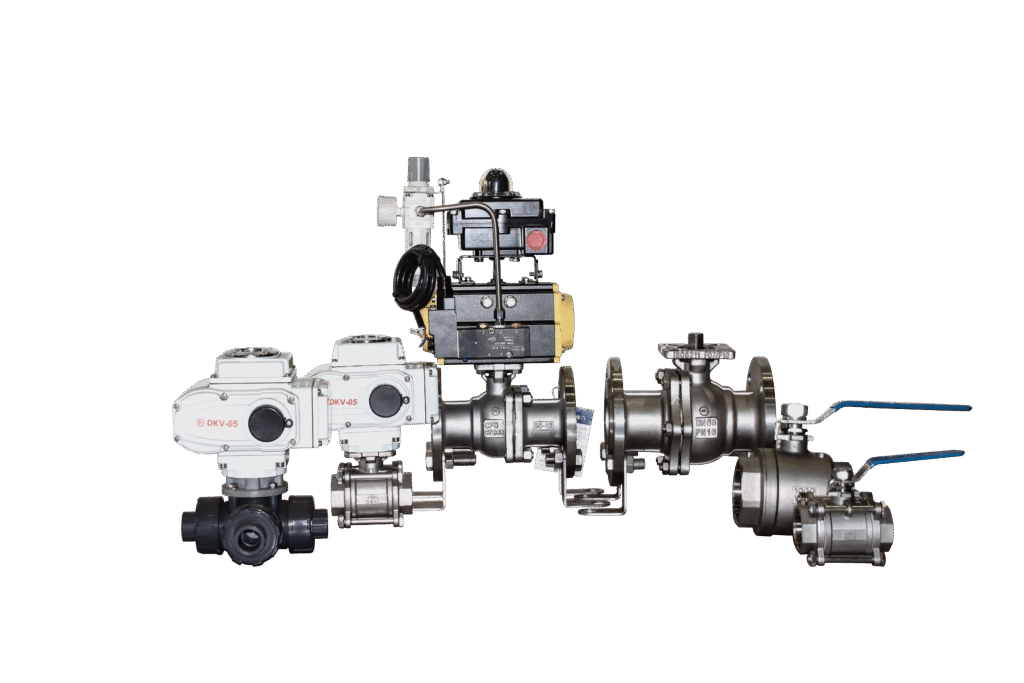

DKV Valve delivers premium ball valve solutions trusted worldwide. Since 1981, our team has specialized in the design and manufacturing of reliable ball valves in China. We supply ball valves in a wide range of materials, including stainless steel, cast steel, brass, and cast iron, to meet diverse industrial applications. Get in touch with us today to learn more about our ball valve products and customized solutions.

Showing 1–12 of 16 resultsSorted by price: low to high

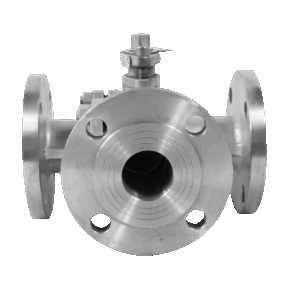

At DKV VALVE, we recognize the critical role ball valves play in ensuring safe and efficient fluid control within pipeline systems. Our industrial ball valves are engineered with advanced designs and manufactured under strict quality standards, holding CE, ISO, and TS certifications.

By choosing DKV ball valves, you gain reliable shutoff performance, long-term durability, and the confidence of proven quality assurance for your projects.

Selecting the right material for ball valves is crucial to ensure consistent performance, long service life, and safe operation in different industries. The choice of material depends on working pressure, operating temperature, compatibility with the process media, and external environmental conditions. Ball valves are commonly manufactured in stainless steel, carbon steel, brass, and cast iron. Each material offers specific strengths—from corrosion resistance to cost efficiency and high-pressure capability. Below, we highlight their operating ranges, recommended applications, and unique benefits to help you choose the most suitable ball valve for your system.

Temperature Range: -20°C to 200°C

Environment: Ideal for corrosive or sanitary applications (e.g., chemical processing, food and beverage, marine systems)

Media: Compatible with acids, alkalis, steam, water, oil, and gas

Features: Excellent resistance to corrosion with strong mechanical properties. Stainless steel ball valves offer smooth flow control, tight sealing, and long service life, making them suitable for extreme temperatures, high-pressure pipelines, and industries that demand both durability and hygiene.

Temperature Range: 0°C to 60°C

Environment: Lightweight, low-pressure systems (e.g., irrigation, water treatment, swimming pools, residential plumbing)

Media: Water, weak acids, and non-corrosive chemicals

Features: PVC ball valves are lightweight, easy to install, and resistant to many chemicals. Cost-effective and corrosion-proof, they are ideal for low-pressure and non-metallic piping applications where durability and ease of maintenance are required.

Temperature Range: -29°C to 425°C

Environment: High-pressure and high-temperature industries (e.g., oil & gas, petrochemical, power generation)

Media: Steam, oil, gas, and aggressive fluids

Features: Cast steel ball valves provide exceptional strength and stability under extreme conditions. They are engineered for critical applications that require reliable shutoff, pressure resistance, and long service life, making them a preferred choice for demanding industrial systems.

Temperature Range: -20°C to 150°C

Environment: Residential, commercial, and light industrial use (e.g., plumbing, HVAC, gas lines)

Media: Water, air, oil, and non-corrosive fluids

Features: Brass ball valves are durable, easy to machine, and resistant to dezincification. They provide excellent sealing performance at a competitive price, making them a popular choice for household systems, commercial facilities, and low to medium-pressure pipelines.

Let’s build the world together.

Selecting the right connection type for ball valves is critical to achieving reliable performance, leak-free operation, and long-term system efficiency. Depending on the pipeline design and industry requirements, ball valves can be connected in several ways, such as threaded, flanged, or welded ends. Each option offers unique benefits in terms of installation, pressure handling, and maintenance convenience. Below, we outline the common ball valve connection methods, their suitable applications, working pressure ranges, and key advantages to help you choose the best fit for your system.

Applications: Best suited for small-scale or low-pressure systems such as residential plumbing, irrigation, and light industrial equipment.

Pressure Range: Typically up to 300 psi

Features: Compact design and easy installation without welding or flanging. Threaded ball valves are cost-effective and convenient for quick assembly, but they are less suitable for large diameters or heavy-duty applications.

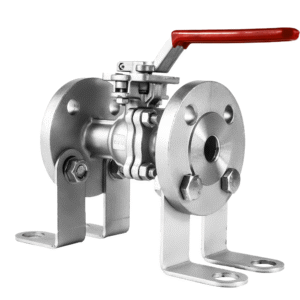

Applications: Widely used in industrial pipelines that require frequent inspection, cleaning, or maintenance, such as water treatment plants, chemical processing, and oil & gas facilities.

Pressure Range: Can handle up to 2500 psi depending on design standards

Features: Flanged ball valves offer robust sealing through bolts and gaskets, ensuring excellent leak resistance. They are easy to disassemble for servicing, but require more space and higher installation costs compared to threaded types.

Applications: Ideal for permanent, high-pressure and high-temperature systems, such as power generation plants, petrochemical pipelines, and critical process industries.

Pressure Range: Exceeds 2500 psi

Features: Welded ball valves provide leak-tight, permanent connections that eliminate gasket failure risks. They are particularly suitable for vibration-prone environments and critical pipelines. However, they cannot be easily disassembled and require skilled welding (e.g., butt-weld per ASME B16.25) during installation.

Applications: Commonly used in hygienic and sanitary systems such as food & beverage, pharmaceutical, and biotech industries, where frequent cleaning or sterilization is required.

Pressure Range: Generally suitable for low to medium-pressure pipelines (up to 150 psi, depending on design).

Features: Clamp ball valves are designed for quick assembly and disassembly without tools, making them ideal for systems requiring regular maintenance. They provide smooth, crevice-free surfaces that meet sanitary standards, ensuring contamination-free fluid control. While easy to clean and maintain, they are less suitable for high-pressure or heavy-duty industrial applications.

Poly Center T41601, Le Cong Town, Shunde District, Foshan City, Guangdong Province, China

We will contact you within 1 working day, please pay attention to the email with the suffix “dkvchina.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@dkvchina.com”.